What Are Additive Packages For Lubricants?

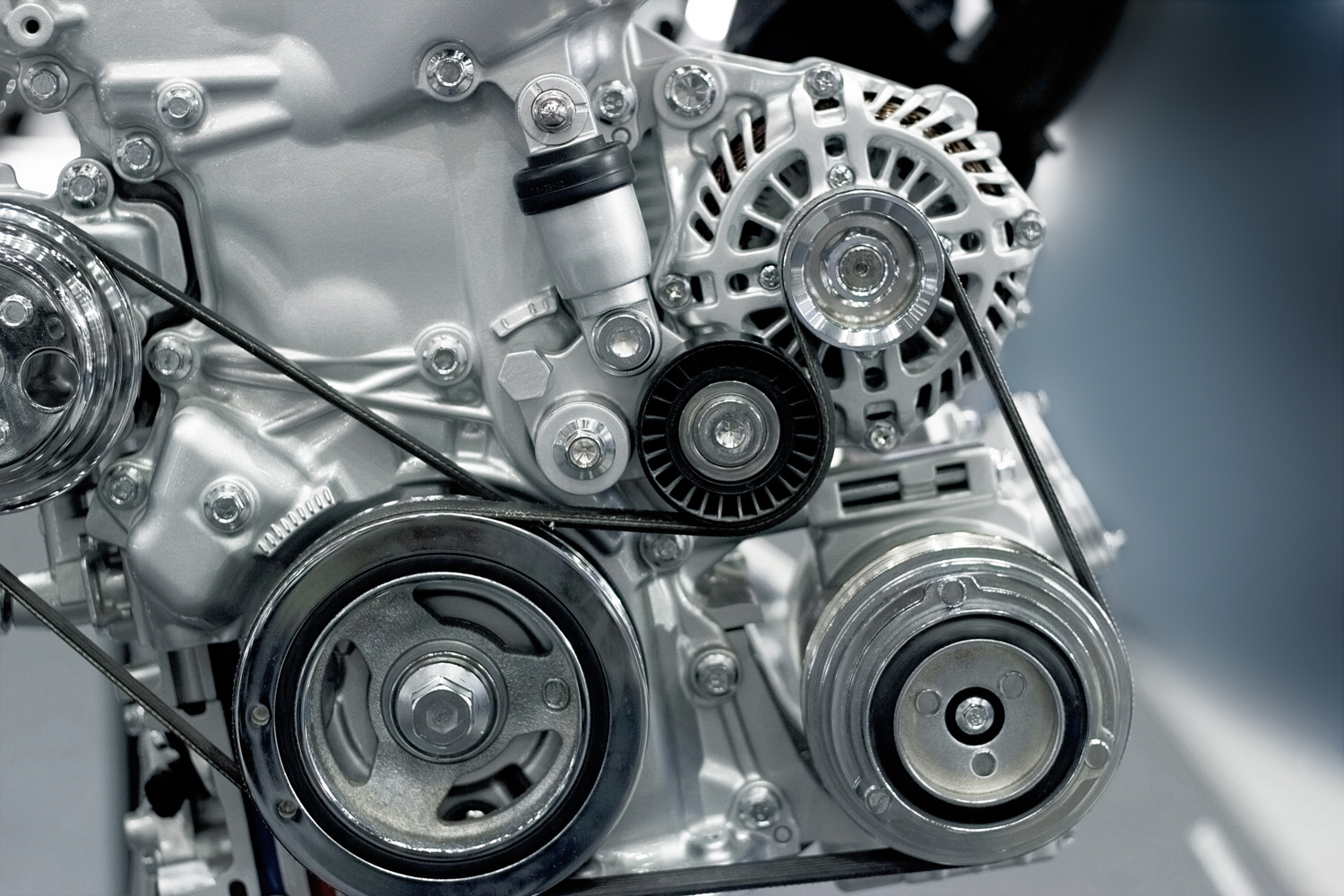

Additive packages are a blend of various chemicals mixed into lubricants to improve their performance and protect machinery. These additives help improve the properties of base oils, making them more effective in a range of applications. From reducing friction to preventing wear, corrosion, and oxidation, additive packages are important for ensuring that lubricants function optimally under varying conditions.

To achieve these benefits, it’s essential to understand the role of different additive packages for lubricants. Here’s what you should know about them:

Additive packages:

Additive packages are combinations of chemical compounds mixed with base oils to create high-performance lubricants. Each package is formulated to meet specific requirements, such as improving viscosity, preventing rust, or reducing foam. These additives work together to improve the overall functionality of the lubricant, ensuring equipment runs smoothly.

Types of additives:

Additive packages typically include several types of additives to address various challenges:

- Antioxidants: Prevent the lubricant from degrading due to oxidation, extending its service life.

- Anti-wear agents: Reduce friction and protect metal surfaces in high-pressure conditions.

- Detergents: Keep internal surfaces clean by preventing the formation of deposits.

- Viscosity improvers: Ensure the lubricant remains effective across a wide temperature range.

- Corrosion inhibitors: Protect machinery components from rust and chemical damage.

Importance in industrial applications:

Modern machinery operates under extreme conditions, including high temperatures, heavy loads, and exposure to contaminants. Additive packages ensure lubricants can withstand these conditions, providing consistent performance. By reducing wear and tear, these packages help lower maintenance costs and extend the lifespan of machinery.

Customization and compatibility:

Additive packages can be tailored to suit specific industries, such as automotive, marine, or industrial equipment. Ensuring compatibility between the additive package and the base oil is key for achieving the desired performance. Selecting the right package is key to meeting operational requirements.

Benefits of using additive packages:

- Improved protection against wear and tear

- Improved temperature stability and viscosity control

- Extended lubricant life

- Prevention of rust and corrosion

- Better overall equipment efficiency

Additive packages are essential for modern lubricants, changing basic oils into highly effective solutions for machinery. Understanding their role and benefits ensures optimal performance and longevity, making additive packages for lubricants a key component of any lubrication strategy.